Description

Stainless steel heat exchanger is the most widely used type heat exchanger made by stainless steel. It has very good anti-oxidation properties,safe and hygienic, can be used at high temperature and high pressure,so it canbe widely use in food, medicine, heating, domestic water and other fields. Stainless steel has better heat transfer effect than the carbon steel, and the service life is longer.

The structure of stainless steel shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube plate, baffle and lid/head. The shell is mostly cylindrical type, with tube bundles installed inside, and both ends of the tube bundles are fixed/welded on the tube plate. Two fluids, hot and cold, for heat exchange, one flows inside of the tubes, called the tube-side fluid; other flows outside the tube, called the shell-side fluid. In order to improve the heat transfer coefficient of the fluid outside the tube, several baffles are usually installed in the shell. The baffle can increase the velocity of the fluid on the shell side, forcing the fluid to pass through the tube bundle several times laterally according to the prescribed path, and enhance the degree of fluid turbulence. The heat exchange tubes can be arranged in equilateral triangles or squares on the tube sheet. The equilateral triangle arrangement is relatively compact, the fluid outside the tube has a high degree of turbulence, and the heat transfer coefficient is large; the square arrangement is convenient for cleaning outside the tube, and is suitable for fluids that are prone to scaling.

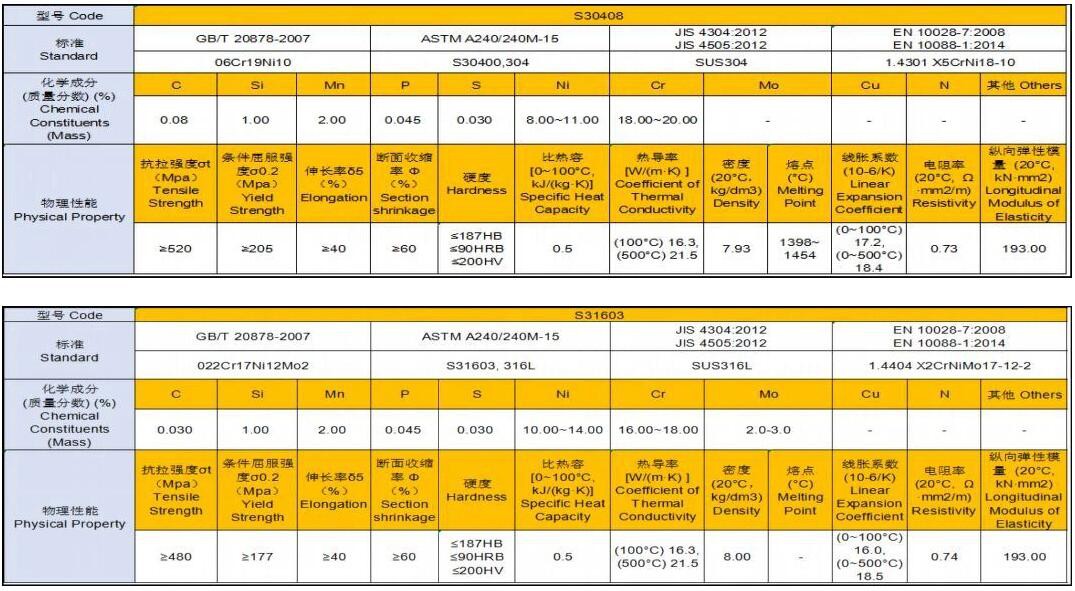

Model/Code/Type 304, 316L are chromium-nickel alloys that common use stainless steel material for shell and tube heat exchanger .

ADVANTAGE OF PRODUCT

High efficiency and energy saving, heat transfer coefficient of SST heat exchanger is 6000-8000W/m2 ℃;

Long service life, up to more than 20 years;

Changing laminar flow to turbulent flow for improve heat exchange efficiency and reduce thermal resistance;

Fast heat exchange speed, high temperature resistance (400℃) and high pressure resistance (2.5Mpa);

Wide application conditions, suitable for high pressure, temperature range and heat exchange of various media;

Low maintenance cost, easy to operate, long scale cycle and easy cleaning;

Compact structure, small footprint, light weight and easy installation.

PROPERTY OF COMMON USE SST MATERIAL

Stainless steel is a group of ferrous alloys that prevents the iron from rusting. Stainless steel's resistance to rusting results from the presence of chromium in the alloy, which forms a passive film that protects the underlying material from corrosion attack. Model/Code/Type 304, 316L are chromium-nickel alloys that common use stainless steel .

CAUTION

Stainless steel corrodes rapidly in the presence of chloride ions, even more than ordinary mild steel. Therefore, there are requirements for the use environment of stainless steel, and it needs to be wiped frequently to remove dust and keep it clean and dry.

CONTACTCERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.