PRODUCT DESCRIPTION

PPS-alloy heat exchanger is a new type shell & tube heat exchanger that utilizes PPS-alloy material tubes as a heat transfer element. It is especially suitable for extreme environments of strong corrosion and high wear in industries such as chemical, petroleum, pharmaceutical and low-temperature waste heat recovery of power plant and steel plant, seawater desalination. Its excellent heat exchange efficiency and corrosion resistance can meet the urgent needs of energy saving, emission reduction and environmental protection.

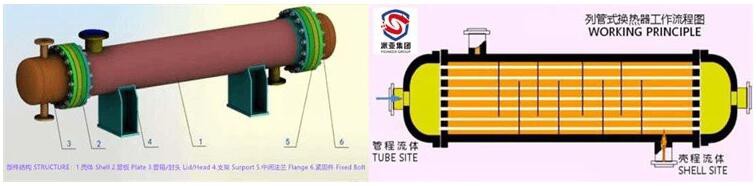

Like other tube-shell type heat exchanger, PPS-alloy heat exchanger consists of shell/body, PPS-alloy heat exchange tube bundle, lid/head, baffle, tube plate,seal & connected flange. It has simple and compact structure in lower cost.

PPS-alloy shell-tube type heat exchanger canbe special designed for various applications. Suitable components should be assembled depending on charactor of specific process/working medium. The shell & plate material canbe use by stainless steel, PTFE/PFA lined steel,glass lined steel, precious metal, alloy metal according to the requiements of anti-corroson & working temperature. According to the corrosion character and working temperature of different heat exchanging mesium, the O type seal material is PTFE and FKM(Viton) between PPS-alloy tube and plate.

PPS-alloy tubes is a polymer composite material made of polyphenylene sulfide resin and reinforced material through injection molding or extrusion process. It has the advantages of light specific gravity, strong chemical corrosion resistance, excellent electrical insulation performance, high impact resistance, simple processing and molding, high thermal conductivity and low cost. It can be used as an excellent substitute for traditional corrosion-resistant and heat transfer materials such as graphite, glass lined, stainless steel, precious metal titanium, tantalum, Hastelloy, fluoroplastics and so on.

The specific gravity of PPS alloy tube is aprox. 1.7, during use PPS alloy tube as a heat transfer element, the max. service temperature is 200 ℃, and the long-term reliable service temperature under pressure is 160 ℃; The bursting pressure canbe reach 4MPa and the long-term service pressure is 0.6MPa.

High Thermal Conductivity - The thermal conductivity of PPS-alloy tube is 5W/(m·K) in vertical direction and 22W/(m·K) in lengthwise, lengthwise value is higher than most corrosion-resistant metals and glass lined steel, graphite material tube. When apply as heat transfer element in heat exchanger, it uses less heat exchange area under the same heat transfer efficiency, allowing smaller size and reducing space occupation

Outstanding Corrosion Resistance - PPS alloy material has extremely high corrosion resistance, oxidation resistance and erosion resistance. It can resist the corrosion of organic solvents and 0-37% hydrochloric acid, 0-40% sulfuric acid, phosphoric acid, 5% nitric acid, 30-50% sodium hydroxide and other media. Its corrosion resistance performance can be compared with PTFE and silicon carbide materials, but the cost is much lower.

Excellent Flame Retardancy - PPS is a high flame retardant material in plastics, up to UL94V-0 grade.

High Wear Resistance and Low Water Absorption - PPS has high wear resistance, and its modulus at 1000 rpm is only 0.04g; The water absorption of PPS is very small, generally only about 0.03%.

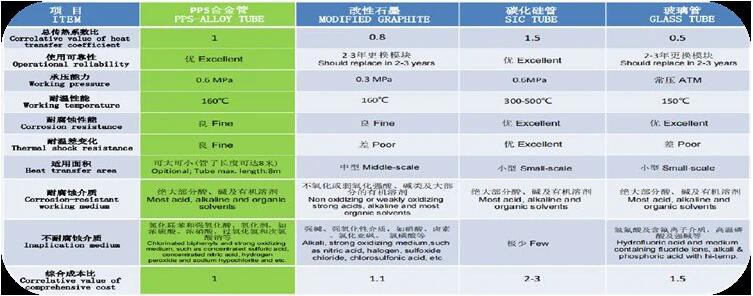

The comprehensive operating cost of PPS-alloy heat exchanger is lower than graphite, silicon carbide and metal matrial type as such list.

CONTACTCERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.