Description

Glass lined shell and tube heat exchanger offers a roster of capabilities to meet high-corrosion, high pressure, full vacuum, high temperature process needs effectively. It can cope with the most stringent demands for product purity, process versatility and ease of maintenance and widely used in chemical, pharmaceutical, pesticide, dyestuff, food and other industries. It can replace expensive metal, such as titanium, nickel, tantalum, hastelloy, alloy materials and so on.

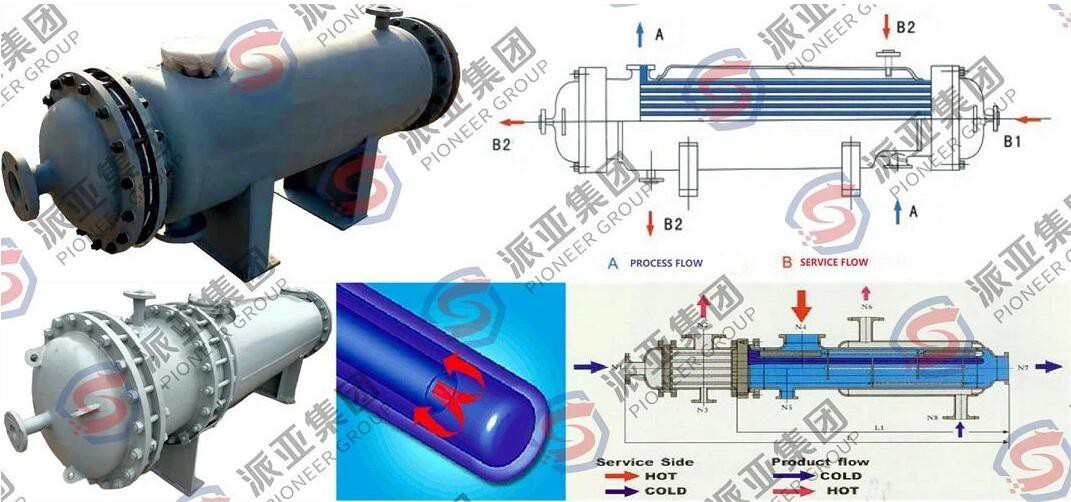

There have two typical designed structure for glass lined shell and tube heat exchanger:

One is based on the traditional tube-shell design with double fixed tube plates like other metal type heat exchanger. This type glass lined heat exchanger consists of shell/body, glass lined tube bundle, both-side lids/heads, baffle, double tube plate, seal system& connected flange.Additional heat exchange area can be created with a jacket around the heat exchanger shell. It has simple and compact structure in lower cost.

Another structure design is a single tube plate with plug-in type. The glass-lined heat exchanger tubes are fastened individually to a tube plate, and then plug in a shell/vessel integrally. This type glass lined heat exchanger consists of shell/body, middle shell, lid/head, glass lined tube bundle, introduction pipe bundle, baffle, tube plate, seal system& connected flange. Additional heat exchange area can be created with a jacket around the heat exchanger shell. Features of this structure is easy to assembly and maintenance, and the glass-lined tubes can be replaced individually if the glass on one of them is damaged.

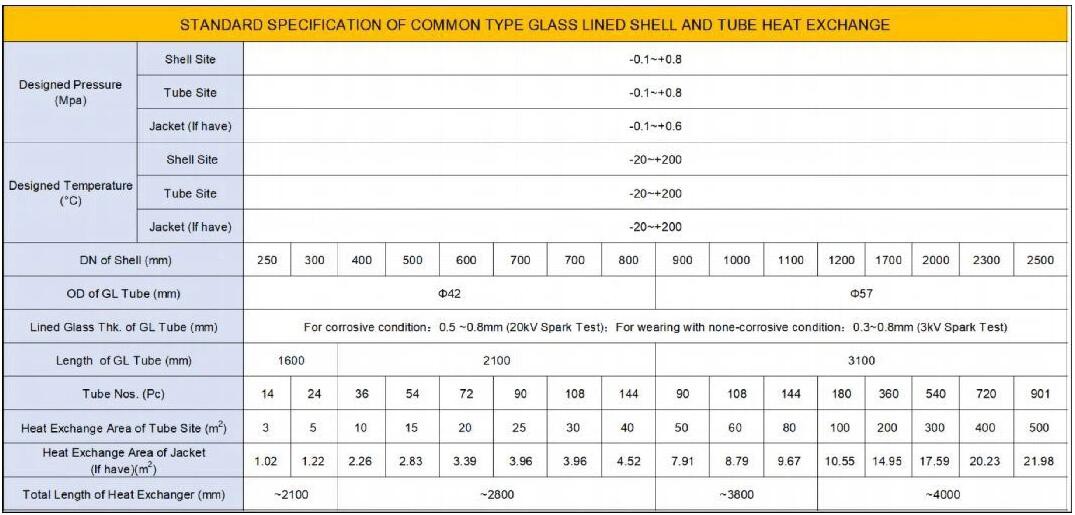

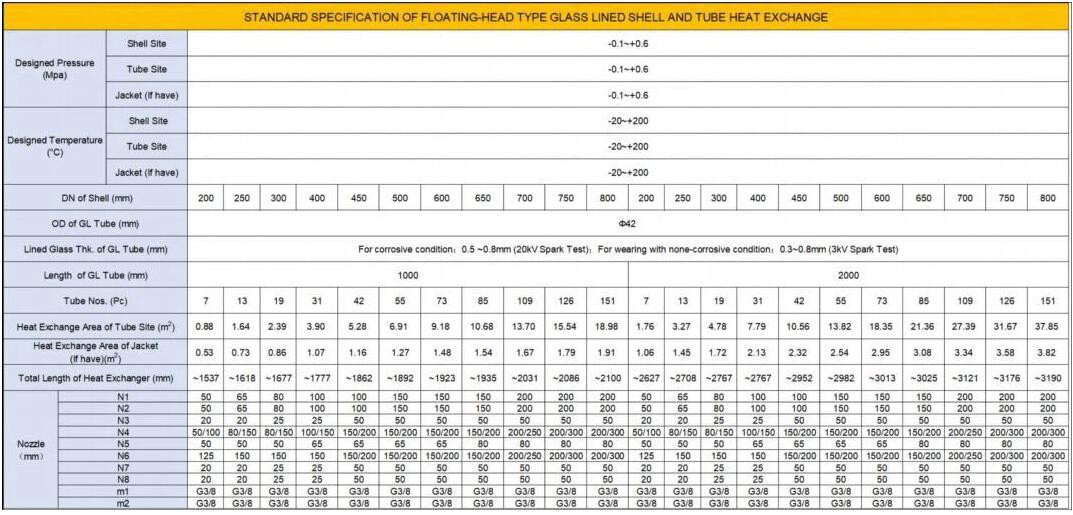

PRODUCT SPECIFICATION

CONTACTCERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.