Description

The structure of titanium or titanium alloy reactor is same as stainless steel reactor mainly includes a top cover with nozzles, a integral closed vessel, a top insert agitator, motor-gear driving device, shaft seal, U type or limpet type heating/cooling jacket, bottom flush valve, temperature and pressure measurement device, CIP/SIP device and etc. Titanium alloy reactor is used in the chemical and petrochemical industries primarily for corrosion resistance. Titanium is harmless to human body, so the titanium reactor canbe use in pharmaceutical or foodstuff.

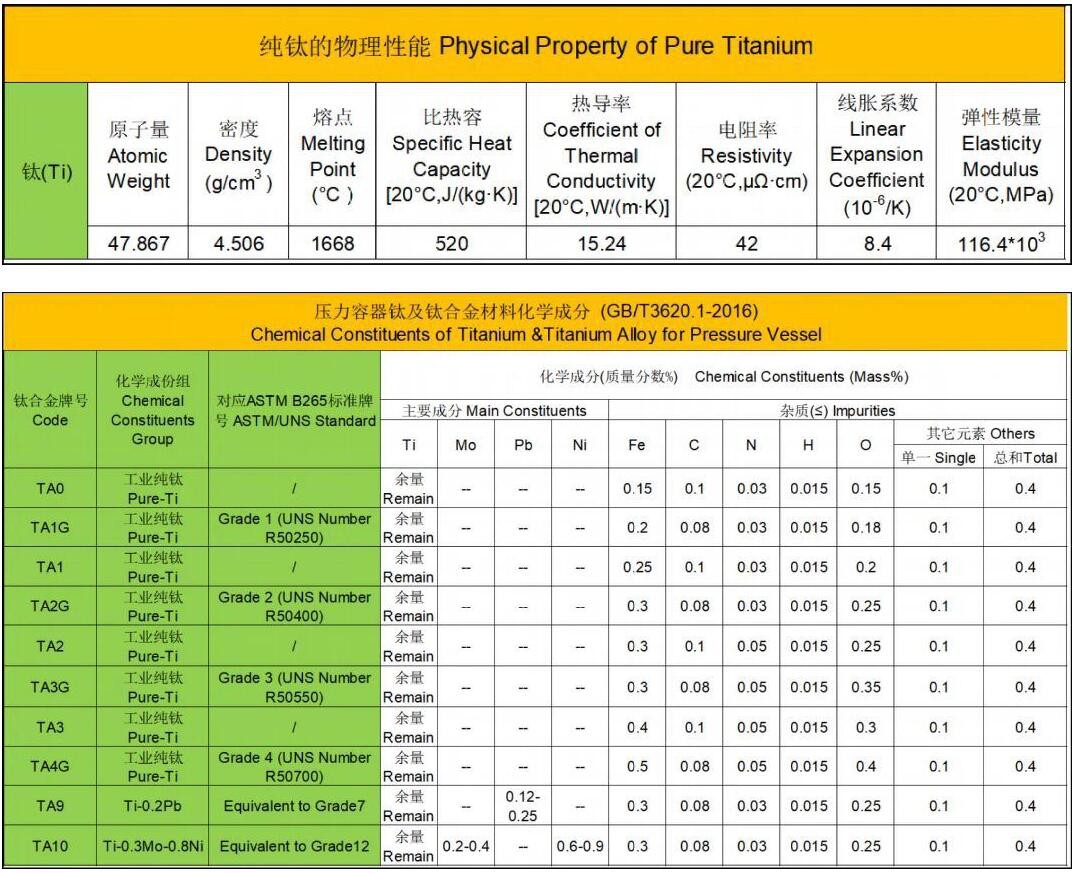

Model TA1,TA2,TA3,TA4 are commonly use pure titanium, and Model TA9,TA10 are titanium alloy.

PRODUCT SPECIFICATION

|

Capacity |

50 to 10000 Liters |

|

Designed Pressure of Vessel |

-0.1-1.6 Mpa |

|

Designed Pressure of Jacket |

0.6 Mpa |

|

Jacket Type |

U Type or Semi-coil Type |

|

Designed Temperature |

-60 to 230 ℃ (Pure-Ti) |

|

Agitator Type(Optional) |

As cutomized |

|

Drive Device for Agitating |

Flameproof AC Motor (Optional) with Vertical type Reducer |

|

Shaft Seal |

Single Type Mechanical Seal (<0.4 Mpa); |

|

Hydraulic Test |

1.5 times designed pressure for jacket & vessel |

|

Design Standard |

GB/T150.1~4-2011,TSG21-2016/XG1-2020, JB/T4745-2002 ; |

|

Nozzle & Flange Standard |

HG/T(GB), ASME, JIS, DIN (Optional) |

PROPERTY OF COMMON USE TITANIUM ALLOY

Titanium and titanium alloy has excellent corrosion resistance than carbon steel, alloy steel, stainless steel and aluminum in many media. The excellent corrosion resistance of titanium comes from the dense titanium dioxide passivation film formed on the surface in air, oxidizing or neutral aqueous medium, especially for chlorine-containing medium.

Titanium and titanium alloy has light weight and high strength compare with carbon steel, alloy steel, stainless steel and , but the thermal conductivity is worse than the above materials and more expensive.

CAUTION

Titanium and titanium alloy vessel should be avoided or used with caution for the fuming nitric acid, dry chlorine, methanol, ethanol, trichloroethylene, liquid nitrogen tetroxide, molten metal salt, carbon tetroxide, urinary pyridine, oxygen, bromine vapor, because titanium will cause combustion, explosion or stress corrosion by contact with the above media under certain conditions.

Also, titanium will burn in pure oxygen with temperature over 500 ℃ or air with temperature over 1200 ℃, so titanium vessel should not be exposed to flame when it exposed to air and oxygen.

Titanium and iron ions can cause galvanic corrosion, and sometimes lead to cathodic hydrogen evolution of titanium, resulting in local hydrogen embrittlement of the vessel. Therefore, the titanium vessel should avoid iron ion and hydrogen pollution during the manufacturing and operating.

Titanium or titanium alloy vessel has not good corrosion resistant property in some media, such as hydrofluoric acid, fluorosilicic acid, hydrochloric acid with concentration higher than 3%, fuming nitric acid, sulfuric acid with concentration higher than 4%, non aerated boiling formic acid, etc.

The use temperature shall be lower than 93 ℃ by titanium or titanium alloy vessel use with caustic soda and other high concentration alkaline solutions.

CERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.