Description

CE type glass lined reactor is full-closed structure vertical type agitating pressure vessel, also named "Close type MSGLR" or "Monoblock type MSGLR". It is design and manufacture according to the DIN-EN standard, and its structure mainly a full closed glass lined vessel body with U type jacket or external limpet coil jacket, a top insert glass lined agitator, motor-gear diving device, shaft seal, flush valve, temperature and pressure measurement device and etc. Heating and/or cooling method is with the jacket through by medium of steam, water or thermal oil.

Design and manufacture standard of CE type glass lined reactor is according to DIN28136 and ASME Section Ⅷ Div. 1 Unstamped, material system can be according to ASME/ASTM standard.

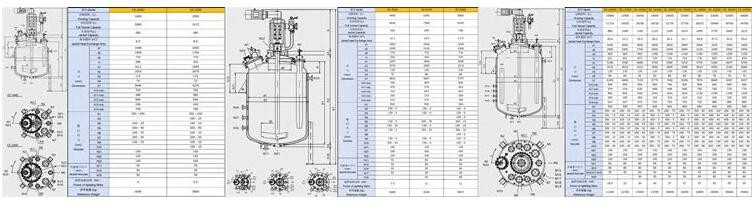

PRODUCT SPECIFICATION

ACCESSORIES FOR GLASS LINED REACTOR

ADAPTATION DESIGN FOR CUSTOMERS

Confirmation of customized terms - Working media, operating ambient, power supply, connect flange standard, required documents and etc.

Structure Design - Calculating result and 3D model validation of capacity, pressure, stress, welding strength, nozzle, flange according to the updated national or overseas standard, rules, material and license system , and reserve certain margin.

ADVANCED GLASS LINED STEEL COMPOSITION PROCESS

Composite Firing Equipment - Underground electric furnace with automatic firing curve (temperature) control system

High Performance Glass Lining/Enamel - The formula of glass lining/enamel is according to the corrosion performance of working medium & process requirement

Advanced Composite Firing Process - Glass lining/Enamel powder cooling spray coating and hi-temperature curve slowly firing process to assure the glass and steel combined more compact (circle with Coat-Dry-Fire-Cool)

Pre-firing & Grit Blasting - Remove impurities and oxide layer on the surface of steel structure, and helps to reduce built-in stress from welding and improve the adhesion of glass lining/enamel

Coating Surface Grinding - By manual grinding coating surface defects

Ground Layer Coating & Firing - The ground coat is specially formulated with emulsifying agents to promote adherence to the steel with no any corrosion resistance. After spray the ground coat onto the prepared steel tank it is allowed time to dry under room temp., then transported to an electric furnace, slowly raise temp. from 350~400℃ till max. temp. 920~940℃ in 4 to 5 hours, and remain 2 hours then slowl

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.