Description

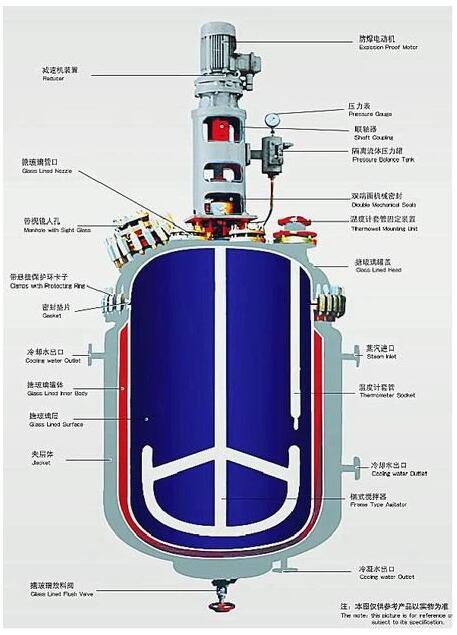

Glass-lined reactor is kind of pressure vessel which combine the inside glass fusion with the outside steel structure into one body, it is resistant to attack from most chemicals and to mixtures of corrosive materials that is used in a wide range of chemical processes that involve harsh chemicals. Glass-lined reactors are meticulously produced with an impermeable, smooth, anti-stick surface that achieves an optimum balance of corrosion resistance, thermal properties and mechanical strength.

Open type glass lined reactor is a kind of two-piece vertical type pressure vessel equipment with agitator, also named "Flange type" or "Clamped type". Its structure mainly includes a removable glass lined top cover that attaching and sealing to a glass lined vessel body by flange, gasket and hook-shaped clamps to a integral closed vessel, a top insert glass-lined agitator, motor-gear driving device, shaft seal, U type or limpet coil type heating/cooling jacket, glass/PTFE lined flush valve, temperature and pressure measurement device and etc. The standard design included two different systems, one is GB Standard K Series, another is DIN28136 Standard AE Series. Heating and/or cooling method is with a u type jacket or outer-side semi-coil jacket through by medium of steam, water or thermal oil.

Divided structure design of open type glass lined reactor can be easily replace the damaged top cover or vessel body separately.

PRODUCT SPECIFICATION

|

Capacity |

50 to 5000 Liters (K series, GB/T25027-2018); |

|

Designed Pressure of Vessel |

0.25 Mpa, 0.6 Mpa,1.0 Mpa |

|

Designed Pressure of Jacket |

0.6 Mpa |

|

Jacket Type |

U Type Or Semi-coil Type |

|

Designed Temperature |

-20 to 200 ℃ (K series) |

|

Thickness of Lined Glass |

0.8 to 2.0 mm (K series) |

|

Agitator Type(Optional) |

Frame/anchor type: 50 to 80rpm with blade end linear speed not more than 5m/s; |

|

Drive Device for Agitating |

Flameproof AC Motor (Optional) with Vertical type Reducer |

|

Shaft Seal |

Stuffing Seal (≤0.25 Mpa); |

|

Spark Test for Lining-glass |

20KV after glass-ling fired, and 10KV before delivery |

|

Hydraulic Test |

1.2 times designed pressure for jacket & vessel |

|

Temperature Resistance |

Chilling shock: 110 ℃, Thermal shock: 120 ℃ |

|

Design Standard |

GB/T150.1~4-2011,TSG21-2016/XG1-2020, GB/T25025-2010, GB/T25027-2018, HG/T20569-2013, (K series); |

|

Nozzle & Flange Standard |

HG/T(GB), ASME, JIS, DIN (Optional) |

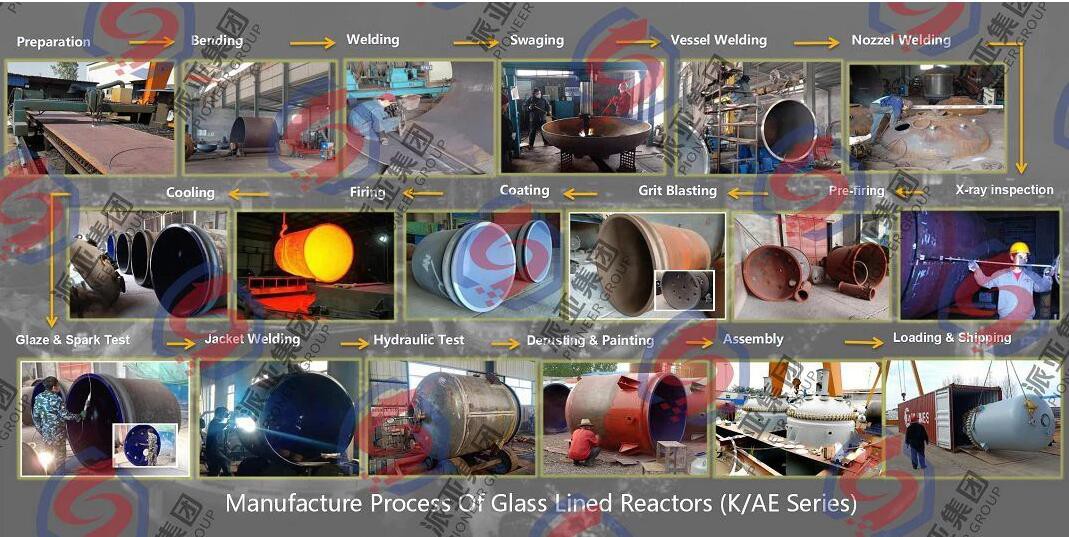

MANUFACTURE PROCESS

FEATURES OF OUR GLASS LINED EQUIPMENT

Corrosion Resistance -The inner lined glass is extremely resistant to corrosion by acids and alkalies (except for hydrofluoric acid and hot concentrated phosphoric acid)

Anti-stick - Many materials will not stick to glass, but will stick to metal

Purity - The inner lined glass has high quality standards for food and drug applications

Flexibility - The glass lined steel can handle a diverse range of chemical conditions

Easy To Clean - glass lining surface enables quick, easy cleaning and sterilization

Absence Of Catalytic Effect - eliminates the possibility of catalytic effect that can occur in vessels made with various exotic metals

Economy - the cost is comparable to stainless steel and most alloys

Excellent Insulation - When does 20KV high-frequency spark testing, the electric spark can not penetrate the lined glass

Temperature Resistance - Thermal conductivity is only 1 to 0.1 percent of metal

Impact Resistance - The impact resistance of superior products is 260*10-3J

Customized Design - Design and manufacture according to the condition and requirement of customer

CERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

PLANTESITE

PLANTESITE

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.