Description

The structure of hastelloy reactor is same as stainless steel reactor mainly includes a top cover with nozzles, a integral closed vessel, a top insert agitator, motor-gear driving device, shaft seal, U type heating/cooling jacket, bottom flush valve, temperature and pressure measurement device, CIP/SIP device and etc. Hastelloy has good corrosion resistance and thermal stability, suitable for various chemical industries containing oxidizing and reducing media. The corrosion resistance of hastelloy is excellent apply in reducing environments, complex mixed acid environments and solutions containing halide ions.Hastelloy is also one of the few metal materials that can resist the corrosion of fluoride ions.

PRODUCT SPECIFICATION

|

Capacity |

50 to 3000 Liters |

|

Designed Pressure of Vessel |

-0.1 to 1.6 Mpa |

|

Designed Pressure of Jacket |

0.6 Mpa |

|

Jacket Type |

U Type |

|

Designed Temperature |

0 to 300 ℃ |

|

Agitator Type(Optional) |

As cutomized |

|

Drive Device for Agitating |

Flameproof AC Motor (Optional) with Vertical type Reducer |

|

Shaft Seal |

Single Type Mechanical Seal (<0.4 Mpa); |

|

Hydraulic Test |

1.5 times designed pressure for jacket & vessel |

|

Design Standard |

GB/T150.1~4-2011,TSG21-2016/XG1-2020, JB/T4756-2006 ; |

|

Nozzle & Flange Standard |

HG/T(GB), ASME, JIS, DIN (Optional) |

PROPERTY OF COMMON USE HASTELLOY MATERIAL

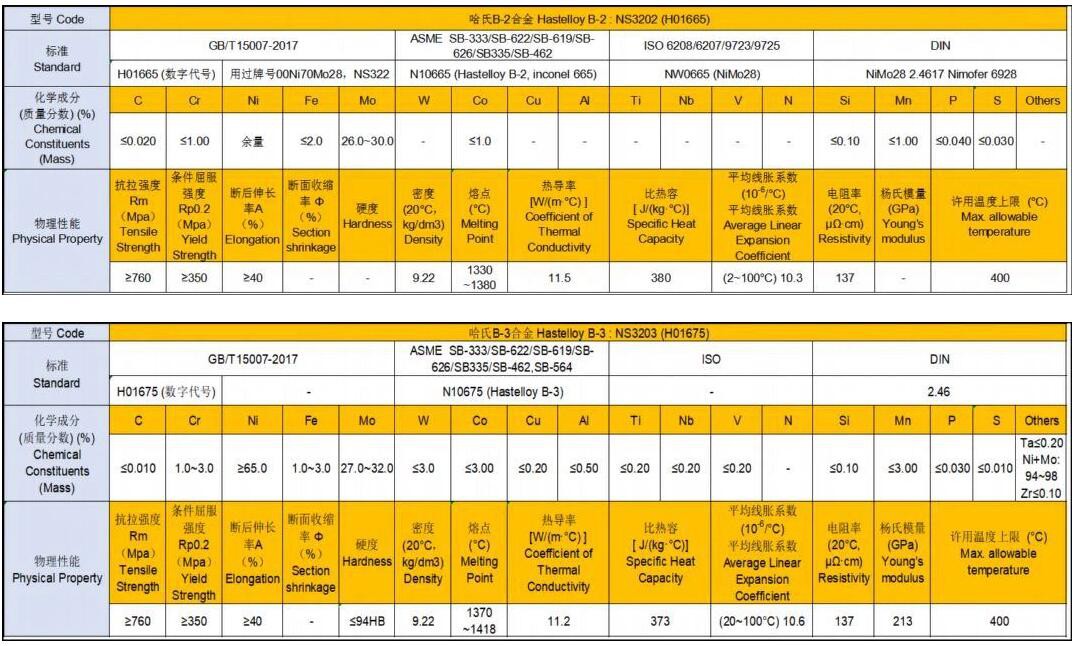

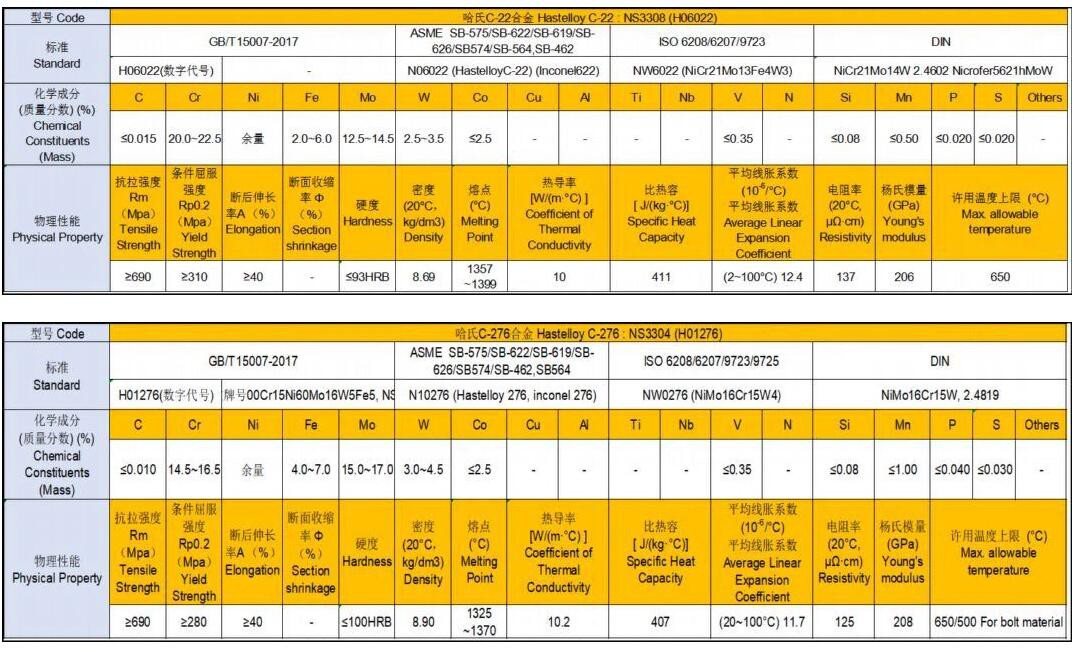

Hastelloy is an ultra-low carbon nickel-based corrosion-resistant alloy, which is mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy. Commonly used as pressure vessels of hastelloy model include B-2 and B-3 (Ni-Mo alloy), C-276 (Ni-Cr-Mo-Fe-W alloy), and C-22 (Ni-Cr-Mo-W alloy).

CAUTION

Hastelloy B series have not good corrosion resistant property in trivalent iron salt and divalent copper salt, so it should be avoided or used with caution.

CERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

PLANTESITE

PLANTESITE

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.