Description

Glass lined storage tank/receiver is an ideal for the storage and containment of corrosive chemicals or high purity pharmaceuticals. Vertical type glass lined storage tank/receiver have advance of small floor area, but capacity is smaller than horizontal type, and should consider the wind load and liquid static load during design.

Vertical type glass lined storage tank/receiver also has two kind of tructure: open or flanged structure, full close or monoblock type.

Vertical flanged type glass lined storage tank/receiver is a type of two pieces glass-lined steel vessel for chemical storage. It comprises a vessel body and a separable cover, and the cover attaching and sealing to vessel body by a flange, a gasket and hook-shaped clamps. It is easy to clean, maintain and repair by open the cover.

Vertical monoblock type glass lined storage tank/receiver is a type of full-closed welded glass-lined steel vessel for chemical storage. By without large main opening maximize top head strength and allow for higher pressure ratings.

General design of glass lined storage tank/receiver is un-jacketed structure, also canbe assembly a U type jacket or semi-coil type jacket or inner coil for heat exchange as customized.

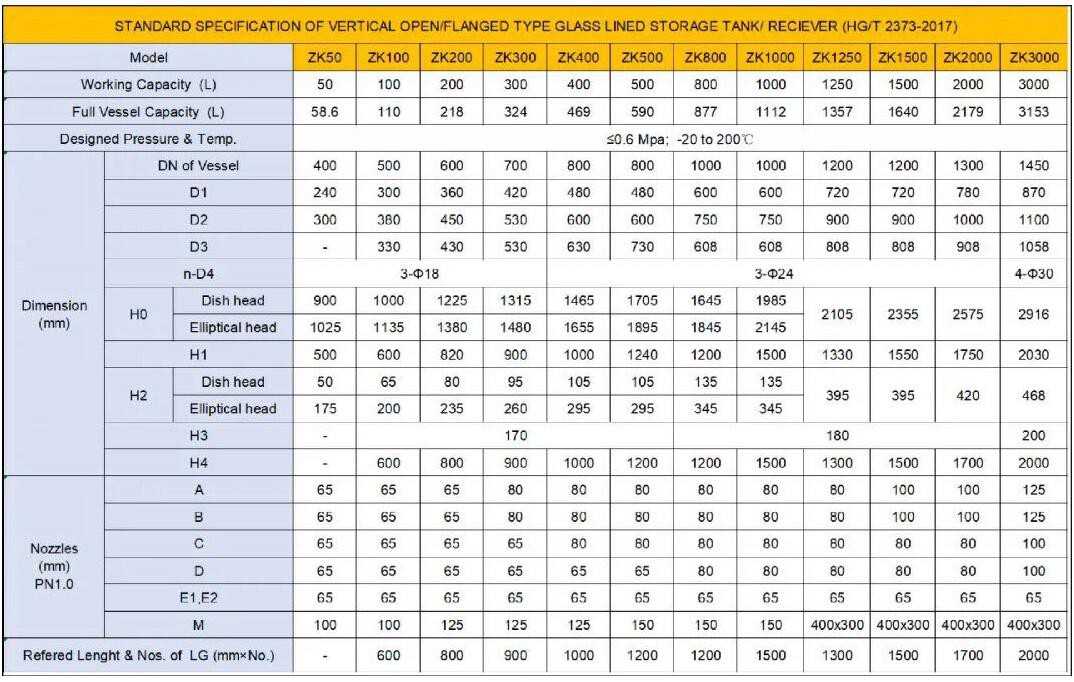

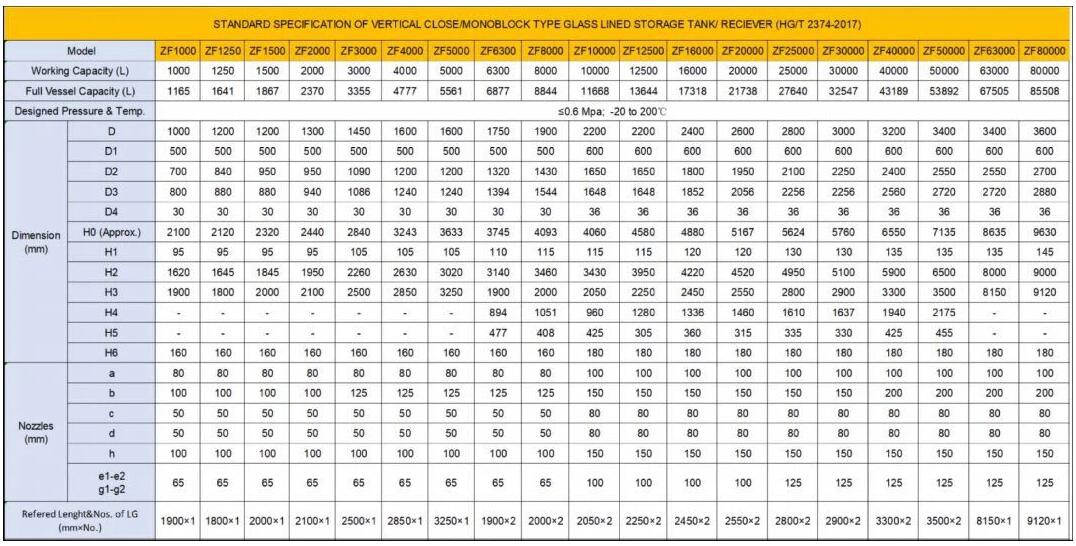

STANDARD PRODUCT SPECIFICATION

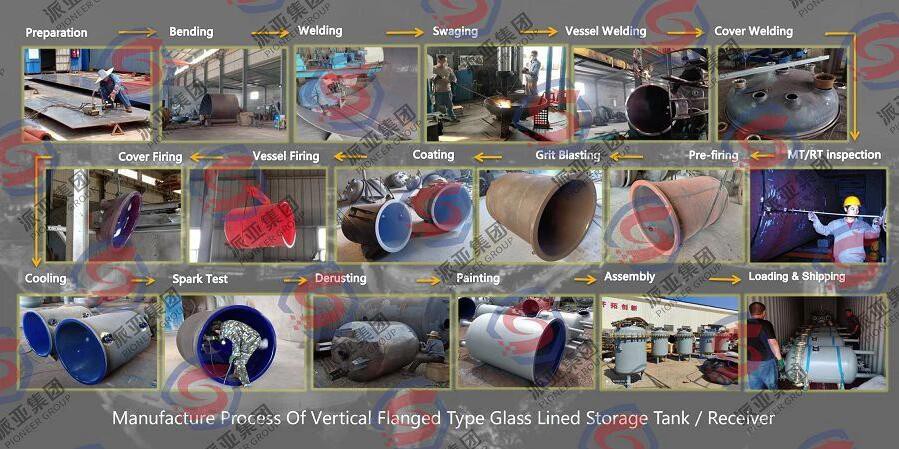

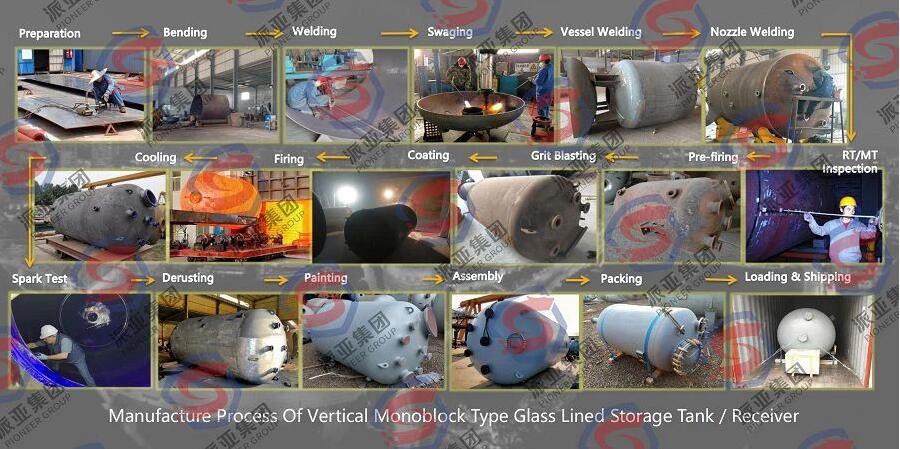

MANUJFACTURE PROCESS

FEATURES OF OUR GLASS LINED EQUIPMENT

Corrosion Resistance -The inner lined glass is extremely resistant to corrosion by acids and alkalies (except for hydrofluoric acid and hot concentrated phosphoric acid)

Anti-stick - Many materials will not stick to glass, but will stick to metal

Purity - The inner lined glass has high quality standards for food and drug applications

Flexibility - The glass lined steel can handle a diverse range of chemical conditions

Easy To Clean - glass lining surface enables quick, easy cleaning and sterilization

Absence Of Catalytic Effect - eliminates the possibility of catalytic effect that can occur in vessels made with various exotic metals

Economy - the cost is comparable to stainless steel and most alloys

Excellent Insulation - When does 20KV high-frequency spark testing, the electric spark can not penetrate the lined glass

Temperature Resistance - Thermal conductivity is only 1 to 0.1 percent of metal

Impact Resistance - The impact resistance of superior products is 260*10-3J

Customized Design - Design and manufacture according to the condition and requirement of customer

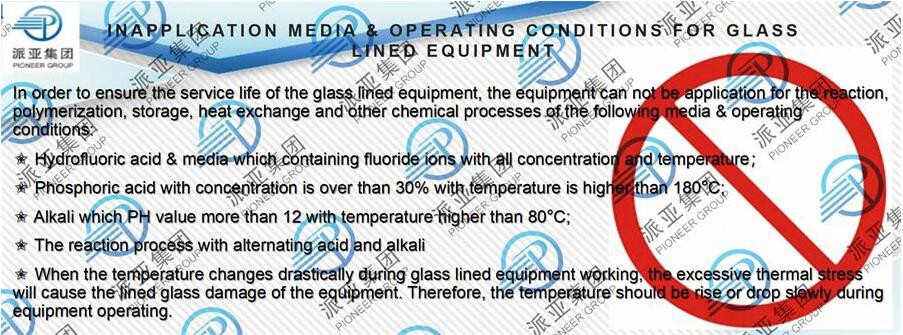

INAPPLICATION MEDIA & OPERATING CONDITIONS FOR GLASS LINED EQUIPMENT

MAJOR FACTORY INSPECTION

◆Mechanical performance test for steel substrate

◆Tensile strength test for clamps

◆Anti-corrosion performance test for glass lining/enamel with test bar or block

◆Weld joint inspection with Head: RT-100% and shell: RT-20%

◆Nozzles position and flatness inspection

◆Visual inspection for the lined glass layer after firing

◆Lined glass thickness detection after firing

◆20kV spark test for the lined glass layer after firing

◆Hydraulic test for Jacket and Vessel

◆10kV spark test and finish inspection for the lined glass layer before delivery

MATERIAL OF CONSTRUCT & ACCESSORIES

Shell/Vessel/Jacket - Q235B(GB/T 3274-2017) / Q245R or Q345R(GB/T 713-2014) from famous brand

High-neck Flange/Manhole Flange/ Nozzles - Q235B(GB/T 3274-2017)/10# or 20# Forged steel(NB/T 47008-2017)

Clamps - 35# Forged steel(NB/T 47008-2017) with surface zinc-plated or chrome-plated

Split Backing Flange- Q245R (GB/T 713-2014) with surface zinc-plated or chrome-plated

Manhole Cover & Protection Ring - Q245R or Q345R(GB/T 713-2014) from famous brand

Gaskets - PTFE envelope type gaskets with corrugated stainless steel ring and Non-Asbestos inserts (HG/T 2050-2019)

CERTIFICATE

VISITORS AND EXHIBITION

EXPORTS

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.