Description

Double cone vacuum dryer(RCVD) also named conical dryer blender (CDB) is a kind of multi-functional machine of mixing & vacuum drying, it is a batch type fully closed process equipment for solid-liquid separation, vacuum drying of powder & granular solid and low -temperature concentrating of reaction solution, which is widely used in chemical industry, fine chemical industry, foodstuffs industry and pharmaceutical process industry. The excellent corrosion resistance, anti-stick and cleanliness of the glass-lined vessel is especially suitable applicating for material that easy to be oxidized, volatilized, heat sensitive & toxic, not permitted to destroy its crystal in drying process, and the solution should tobe recovering.

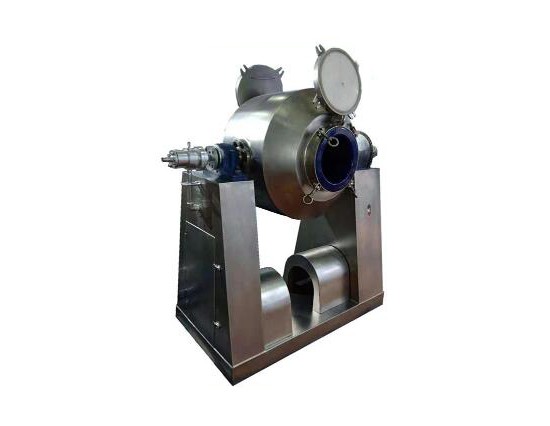

Its constructure mainly includes a glass-lined double-conical vessel, a heating/cooling jacket, a frame, driving system, sealing device, vacuum system, rotary joint, temperature and pressure measurement device, control device and etc.

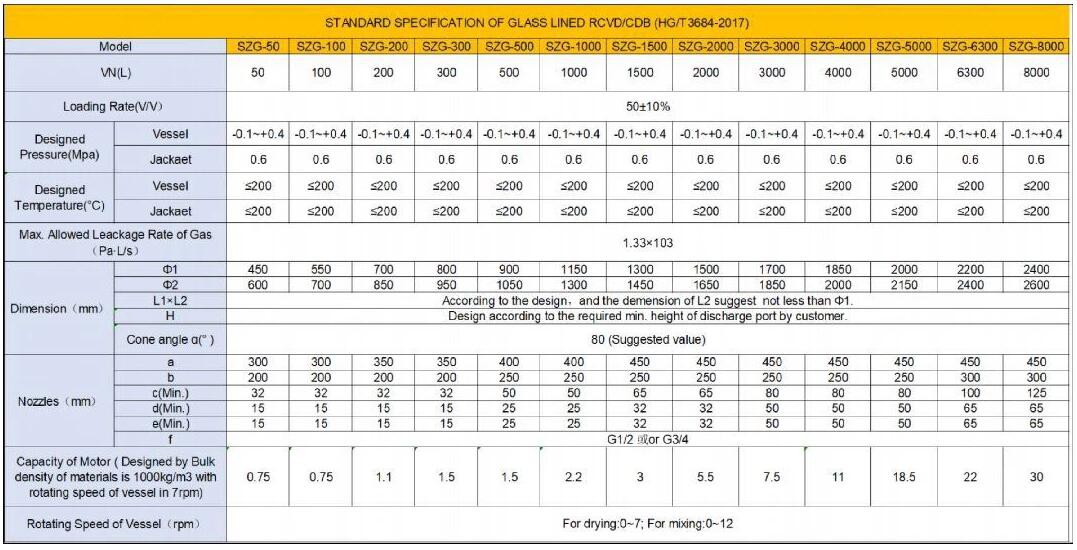

PRODUCT SPECIFICATION

MANUFACTURE PROCESS

APPLICATIONS OF RCVD/CDB

Suitable materials with powder and granular state:

*Heat-sensitive materials that should be drying at low temperature;

*Oxygen-sensitive with hazardous materials;

*Materials that requiring recovery of toxic solvents and gases;

*Materials that required with low residual volatile content;

*Materials that required mixed/blended sufficiently and evenly.

Inapplication materials and operating conditions:

*Hydrofluoric acid & media which containing fluoride ions with all concentration and temperature;

*Phosphoric acid with concentration is over than 30% with temperature is higher than 180°C;

*Alkaline which PH value more than 12 with temperature higher than 80°C;

*When the temperature changes drastically during glass lined equipment working, the excessive thermal stress will cause the lined glass damage of the equipment. Therefore, the temperature should be raised or lowered slowly during equipment operating.

*Materials that easy to agglomerate during drying process

PRODUCT ADVANTAGES

Vacuum Drying - Vacuum drying (VD) has some distinctive characteristics such as higher drying rate, lower drying temperature, and oxygen-deficient processing environment. It is conceptually the ideal method for drying heat and/or oxygen sensitive materials due to the advantage of removing moisture at low temperatures and minimizing the possibility of oxidation reactions. During vacuum drying, high-energy mloisture molecules diffuse to the surface and evaporate due to low pressure. Due to the absence of air and bacteria, vacuum drying prevents oxidation and maintains the color, texture, and flavor of the dried products.Vacuum-drying is proposed to alleviate some disadvantages of hot-air-drying, such as surface hardening and dispersion. During vacuum drying, the rate of evaporation increases (at a fixed temperature) since the boiling point of moisture is reduced. Vacuum-drying consequently requires less drying time than conventional hot-air-drying and in most cases results in a higher quality dried product.

Multifuctional - The glass lined RCVD/CDB performs a multitude of tasks including mixing/blending, vacuum drying, and recovery of solvents (should connected with condensing system) .

High Applicability - The rotating speed of vessel can be flexibly adjusted through the frequency conversion flameproof motor and controller to adapt to the changes in the specific gravity and viscosity of material, and improve the efficiency of drying process.

Configurability & Cleanliness - Pneumatic control feed/discharge valves, weighing system, CIP/MIP and SIP systems can be added to meet the requirements of GMP standard clean production and automatic control to reduce the cross contamination risk.

CERTIFICATE

OUR PARTNER

VISITORS AND EXHIBITION

FAQ

E-mail:info@cmchemical.net

E-mail:info@cmchemical.net Tel:182-6588-8777

Tel:182-6588-8777 Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.

Address: Room 804, Huaxia International Building, No.96 Liuquan Road, Zhangdian District, Zibo City, Shandong Province, P.R.China.Shandong PIONEER Heavy Industry Technofogy Co., Ltd.